ALUM DOSING AND POLY DOSING IN ETP

COPY RIGHTS : TO AVOID COPYRIGHT VIOLATIONS, ALL POSTS ARE SHOWN ALONG WITH SOURCES FROM WHERE ITS TAKEN. PLEASE CONTACT ME IN MY EMAIL SALEEMASRAF@GMAIL.COM , IF YOU ARE THE AUTHOR AND YOUR NAME IS NOT DISPLAYED IN THE ARTICLE.THE UNINTENTIONAL LAPSE ON MY PART WILL BE IMMEDIATELY CORRECTED.

I HAVE SHARED ALL MY PRACTICAL WATER TREATMENT EXPERIENCES WITH SOLVED EXAMPLE HERE SO THAT ANYBODY CAN USE IT.

SEARCH THIS BLOG BELOW FOR ENVO ,COMPACT STP,ETP,STP,FMR,MBBR,SAFF,IRON,ARSENIC,FLUORIDE,FILTER,RO,UASB,BIO GAS,AERATION TANK,SETTLING TANK,DOSING,AMC.

SEARCH THIS BLOG

Showing posts with label etp. Show all posts

Showing posts with label etp. Show all posts

Monday, October 02, 2023

ALUM dosing AND POLY DOSING IN ETP

Labels:

alum dosing,

envo projects,

etp,

poly dosing,

STP

New Delhi, India

New Delhi, Delhi, India

Environmental Entrepreneur,Green Biz.NRN Murthy of Infosys says that we Indians are weak in execution.We need to realize the need and practice of gud project management. Form a group of competent Managers,Give them responsibilities and review the project from day One.

Environmental Entrepreneur,Green Biz.NRN Murthy of Infosys says that we Indians are weak in execution.We need to realize the need and practice of gud project management. Form a group of competent Managers,Give them responsibilities and review the project from day One.

Thursday, December 05, 2019

Bleaching powder dosing for disinfection in waste water treatment plant

Bleaching powder dosing for disinfection in waste water treatment plant

Sources of Informations given below

Manual http://cpheeo.gov.in/upload/uploadfiles/files/Chapter%206-9.pdf

1. https://www.epa.ie/pubs/advice/drinkingwater/Disinfection2_web.pdf

2.http://jeb.co.in/journal_issues/200710_oct07/paper_04.pdf

The pilot scale disinfection units located at two different UASBR based STPs have been selected for this study. One of these pilot plants has been constructed after 27 MLD UASBR based STP, Noida (Uttar Pradesh, India) and is based on chlorination using calcium hypochlorite (either slurry form or liquid high test hypochlorite, HTH) with a capacity of 2 million liter per day (MLD). The other 1 MLD DHS-biotower pilot plant, developed by Prof. H. Harada (Machdar et al., 1997), is based on fixed film aerobic process and has been constructed after 40 MLD UASBR based STP, Karnal (Haryana, India). These STPs, based on UASBR technology, consists of preliminary treatment (Screen and Grit Chamber), UASBR and final polishing pond (Fig. 1). A schematic diagram of the pilot plants at Noida and Karnal is presented in Fig. 2 and 3 respectively. The chlorination unit of 2 MLD consists of a sump, mixing unit and baffled contact chamber (3m x 7m) and a specific dose of chlorine was mixed with a separate pipe. The 1 MLD DHS-biotower based on fixed film aerobic process consists of a sump and reactor having plastic rectangular sheets onto which triangular prism polyurethane foams were tiled. Raw sewage after UASBR treatment was supplied to the chlorination unit and DHS-biotower

In case of chlorination unit, initially the bleaching powder was used as a disinfectant from day 1 to day 48 and later on it was found that there was no residual chlorine in the bleaching powder, so the bleaching powder was replaced with calcium hypochlorite as disinfectant after 48th day. The dose of disinfectant was 5 mgl-1 from day 1 to day 16 and was increased to 20 mgl-1 from day 20. The contact time for the reaction between wastewater and disinfectant was 30 min throughout the study.

Results and Discussion Reduction of fecal coliform: To achieve good disinfection, the contact time and dose are extremely important. A longer contact time is required for complete disinfection to occur. As per Lindsay (2004), a contact time of 30 minutes is a minimum, and if the dose remains constant, the contact time may necessitated to be increased at low temperatures or higher pH to obtain the same level of disinfection. Typical chlorine doses for municipal wastewater disinfection are about 5-20 mgl-1 with a contact time of 30 to 60 min (Lazarova et al., 1999). During this study, 5 and 20 mgl-1 of disinfectant doses for a fixed contact time of 30 min was applied. It was observed that a dose of 20 mgl-1 was very effective for the reduction in indicator microorganism (fecal coliforms). Initially when a dose of 5 mgl-1 was used, the reduction in fecal coliforms count was less than 90%. It may be attributed to the fact that the minimum dose required for the killing of microorganism was not sufficient as there was high chlorine demand due to the presence of high concentration of organic matter and suspended solids in the UASBR effluent. The average fecal coliforms count was reduced from 3.58 x 105 (± 1.02 x 105 ) MPN/ 100ml to nil at a dose of 20 mgl-1 and 30 min contact time (Fig. 4a). Thus the results shows that almost 100% removal of fecal coliforms has been observed after chlorination; however at certain days i.e., from day 7 to day 14 and from day 44 to day 53 (Fig. 4a), the number of fecal coliforms present in the wastewater effluent after disinfection was increased. It could be explained on the basis of type of chemical used for the chlorination. During this period, bleaching powder was used. Later on it was found that the chemical used at the plant does not have any residual chlorine. Chlorination was switched to the fortified brand of the calcium hypochlorite, high test hypochlorite (HTH). It indicated that chlorination was very effective in the removal of fecal coliforms if the regular operation and maintenance (O and M) is ensured.

Sources of Informations given below

Manual http://cpheeo.gov.in/upload/uploadfiles/files/Chapter%206-9.pdf

1. https://www.epa.ie/pubs/advice/drinkingwater/Disinfection2_web.pdf

2.http://jeb.co.in/journal_issues/200710_oct07/paper_04.pdf

The pilot scale disinfection units located at two different UASBR based STPs have been selected for this study. One of these pilot plants has been constructed after 27 MLD UASBR based STP, Noida (Uttar Pradesh, India) and is based on chlorination using calcium hypochlorite (either slurry form or liquid high test hypochlorite, HTH) with a capacity of 2 million liter per day (MLD). The other 1 MLD DHS-biotower pilot plant, developed by Prof. H. Harada (Machdar et al., 1997), is based on fixed film aerobic process and has been constructed after 40 MLD UASBR based STP, Karnal (Haryana, India). These STPs, based on UASBR technology, consists of preliminary treatment (Screen and Grit Chamber), UASBR and final polishing pond (Fig. 1). A schematic diagram of the pilot plants at Noida and Karnal is presented in Fig. 2 and 3 respectively. The chlorination unit of 2 MLD consists of a sump, mixing unit and baffled contact chamber (3m x 7m) and a specific dose of chlorine was mixed with a separate pipe. The 1 MLD DHS-biotower based on fixed film aerobic process consists of a sump and reactor having plastic rectangular sheets onto which triangular prism polyurethane foams were tiled. Raw sewage after UASBR treatment was supplied to the chlorination unit and DHS-biotower

In case of chlorination unit, initially the bleaching powder was used as a disinfectant from day 1 to day 48 and later on it was found that there was no residual chlorine in the bleaching powder, so the bleaching powder was replaced with calcium hypochlorite as disinfectant after 48th day. The dose of disinfectant was 5 mgl-1 from day 1 to day 16 and was increased to 20 mgl-1 from day 20. The contact time for the reaction between wastewater and disinfectant was 30 min throughout the study.

Results and Discussion Reduction of fecal coliform: To achieve good disinfection, the contact time and dose are extremely important. A longer contact time is required for complete disinfection to occur. As per Lindsay (2004), a contact time of 30 minutes is a minimum, and if the dose remains constant, the contact time may necessitated to be increased at low temperatures or higher pH to obtain the same level of disinfection. Typical chlorine doses for municipal wastewater disinfection are about 5-20 mgl-1 with a contact time of 30 to 60 min (Lazarova et al., 1999). During this study, 5 and 20 mgl-1 of disinfectant doses for a fixed contact time of 30 min was applied. It was observed that a dose of 20 mgl-1 was very effective for the reduction in indicator microorganism (fecal coliforms). Initially when a dose of 5 mgl-1 was used, the reduction in fecal coliforms count was less than 90%. It may be attributed to the fact that the minimum dose required for the killing of microorganism was not sufficient as there was high chlorine demand due to the presence of high concentration of organic matter and suspended solids in the UASBR effluent. The average fecal coliforms count was reduced from 3.58 x 105 (± 1.02 x 105 ) MPN/ 100ml to nil at a dose of 20 mgl-1 and 30 min contact time (Fig. 4a). Thus the results shows that almost 100% removal of fecal coliforms has been observed after chlorination; however at certain days i.e., from day 7 to day 14 and from day 44 to day 53 (Fig. 4a), the number of fecal coliforms present in the wastewater effluent after disinfection was increased. It could be explained on the basis of type of chemical used for the chlorination. During this period, bleaching powder was used. Later on it was found that the chemical used at the plant does not have any residual chlorine. Chlorination was switched to the fortified brand of the calcium hypochlorite, high test hypochlorite (HTH). It indicated that chlorination was very effective in the removal of fecal coliforms if the regular operation and maintenance (O and M) is ensured.

Labels:

bleaching powder,

disinfection,

dosing,

etp,

STP,

wtp

New Delhi, India

New Delhi, Delhi, India

Environmental Entrepreneur,Green Biz.NRN Murthy of Infosys says that we Indians are weak in execution.We need to realize the need and practice of gud project management. Form a group of competent Managers,Give them responsibilities and review the project from day One.

Environmental Entrepreneur,Green Biz.NRN Murthy of Infosys says that we Indians are weak in execution.We need to realize the need and practice of gud project management. Form a group of competent Managers,Give them responsibilities and review the project from day One.

Friday, March 02, 2018

PHILOSOPHY BEHIND ENVO PROJECTS

Saleem Asraf Syed

Imdaadullah, Founder, Syed Envo Protect (I) Pvt Ltd in the year 1994 & ENVO

PROJECTS in the year 2001

ITS NOT POSSIBLE TO

FOLLOW ALL THE THINGS THAT OUR PROPHET (Peace be upon him PBUH) HAD DONE, HE IS

MODEL FOR ALL PEOPLE IN THIS WORLD.

When I was 10-12 yrs old, i heard Maulana Madani (Senior) RA say that if somebody follows just one sunnah steadfastly throughout his life thats sufficient for him. And pray for me that I can do something for the betterment of this world before I die.... Otherwise there is no meaning of my existence in this world. Doctors are making peoples health better...engineers are making living conditions better.... Alims are making spiritual lives better.

The philosophy behind my work in environmental engineering

When I was 10-12 yrs old, i heard Maulana Madani (Senior) RA say that if somebody follows just one sunnah steadfastly throughout his life thats sufficient for him. And pray for me that I can do something for the betterment of this world before I die.... Otherwise there is no meaning of my existence in this world. Doctors are making peoples health better...engineers are making living conditions better.... Alims are making spiritual lives better.

The philosophy behind my work in environmental engineering

NOW HAVE I DONE SOMETHING OR STILL DONT HAVE ANY GOAL IN LIFE.no, I have found in Quran majeed myself that the world is a gift from Allah and nobody has the right to destroy it… .So we don't have any right in making our rivers into drain (read yamuna river,bhorolu river), polluting our air with our car exhaust, littering the greens with solid waste…. I am trying my best in this regard …after forming ENVO.

PREAMBLE OF ENVO

Nature is a gift to us . No individual or organisation has the right dto utilise its resources in such a way that damage or inconvenience is caused to people of society . we all have a social responsibility to protect and preserve a clean and green environment. The goale of profit maximisation and customer satisfaction should be surbordinate to the social need and responsibilities. The present concern has been brought about by the health of humans, living being, tree , structures, monuments and all other things.It was repeatedly mentioned in the Qur'an: Forbidding from spoiling the earth after Allah (Exalted and Almighty) has created it suitable and well prepared for the successive human generations. It announced that Allah does not like spoiling or those who spoil in life, this includes spoiling environment, polluting it or being aggressive with it. Also it is forbidden to abuse it in any way that would make it deviate from the purpose of Allah created it for. This would be like showing ingratitude to Allah, that would cause vengeance from Allah, and becomes like a warning to those who perpetrated this, that severe penalty will almost come upon them as what happened before to the `Aad and the Thamud and those who came after them.

"Who did transgress beyond bounds in the land (in the disobedience of Allah) and made therein much mischief. So your Lord poured on them different kinds of severe torment. Surely your Lord is Ever-Watchful." (89:11-14) Islam urges its followers to have great concern for everything created by Allah, for it is part and parcel of "submission to Allah" to show reverence to all what the Almighty Allah created.

PREAMBLE OF ENVO

Nature is a gift to us . No individual or organisation has the right dto utilise its resources in such a way that damage or inconvenience is caused to people of society . we all have a social responsibility to protect and preserve a clean and green environment. The goale of profit maximisation and customer satisfaction should be surbordinate to the social need and responsibilities. The present concern has been brought about by the health of humans, living being, tree , structures, monuments and all other things.It was repeatedly mentioned in the Qur'an: Forbidding from spoiling the earth after Allah (Exalted and Almighty) has created it suitable and well prepared for the successive human generations. It announced that Allah does not like spoiling or those who spoil in life, this includes spoiling environment, polluting it or being aggressive with it. Also it is forbidden to abuse it in any way that would make it deviate from the purpose of Allah created it for. This would be like showing ingratitude to Allah, that would cause vengeance from Allah, and becomes like a warning to those who perpetrated this, that severe penalty will almost come upon them as what happened before to the `Aad and the Thamud and those who came after them.

"Who did transgress beyond bounds in the land (in the disobedience of Allah) and made therein much mischief. So your Lord poured on them different kinds of severe torment. Surely your Lord is Ever-Watchful." (89:11-14) Islam urges its followers to have great concern for everything created by Allah, for it is part and parcel of "submission to Allah" to show reverence to all what the Almighty Allah created.

We cant be all rounder like our Prophet

(PBUH),but atleast we can excel in one field and serve humnanity as he did.

May Allah accepts my

hard work and bestow his blessings on me and forgive me for the major and minor

SINS I make in every steps

My own DREAM---"ENVO" : and to have its presence

in every state of India. (Your time is limited, so don't

waste it living someone else's life. Don't let

the noise of others' opinions drown out your own inner voice.have the

courage to follow your heart and intuition. They somehow already know what you

truly want to become. Everything else is secondary.

My Passion: My work. of water treatment, to

clean the world gifted by god of the mess humans created. ( Don't lose

faith. I'm convinced that the only thing that kept me going was that I loved

what I did. You've got to find what you love. And that is as true for your work

as it is for your lovers. Your work is going to fill a large part of your life,

and the only way to be truly satisfied is to do what you believe is great work.

And the only way to do great work is to love what you do. If you haven't found

it yet, keep looking. Don't settle. As with all matters of the heart, you'll

know when you find it. And, like any great relationship, it just gets better

and better as the years roll on. So keep looking until you find it. Don't

settle.)

There is still a lot to learn, I try to learn from everybody

and atleast one new thing every day : Stay Hungry. Stay Foolish

The World Only Cares About What It Can Get from You.

Change your attitude towards life. Do not look for perfection

and CONTROL in everything in life. I understood that my livelihood

(RIZQ) cant be taken away by anyone. Put your best efforts in what you do and than

leave the result to ALLAH. I have plan but Allahs plan is much much better than

mine. I have firm belief in ALLAH.

During

this journey many people came and left me. I thank all of them for their

contribution for my growth. They are destined to be with me for that particular

period. This is Allah’s plan.

Always

sleep with a clean heart. I know many of us get wronged throughout the day or

have gotten wronged in the past. Forgive. Not only forgive, but forgive and

forget. Dont even hold a grudge against that person in your heart. Keep your

heart completely pure.Forgive brothers and sisters before you sleep each night.

this is one of the practices of the greatest people ever to live and this is

how we will reach those highest levels of spirituality.

Forgiveness is good for your own well

being, its about giving yourself permission to let go of the painful past. Forgiveness

is not something we do for that particular toxic person,it is something we do

for ourselves so we can move on to a better future.We forgive,not because that

toxic person deserves it,but because we deserve peace, for a pure heart.

Read quran ,Sura 24:22 , sura 2:263 , sura3:133-134 , sura7:199, sura

15:85, sura 45:14

Ending this article with a hadith

Narrated by Abdullah ibn Amr, Prophet Muhammad (PBUH) stated:"Show

mercy and you shall be shown mercy.Forgive others and you shall be forgiven by

Allah."(Musnad Ahmad)

LOVE HUMANITY IRRESPECTIVE OF RELIGION, LOVE ANIMALS, TREES AND ALL OF GODS

CREATIONS. IF YOU CAN NOT LOVE AND ADMIRE GODS CREATION, HOW CAN YOU THINK

ABOUT ADMIRING THE GREATNESS OF GOD.

Read quran ,Sura 24:22 , sura 2:263 , sura3:133-134 , sura7:199, sura 15:85, sura 45:14

Ending this article with a hadith

Narrated by Abdullah ibn Amr, Prophet Muhammad (PBUH) stated:"Show mercy and you shall be shown mercy.Forgive others and you shall be forgiven by Allah."(Musnad Ahmad)

LOVE HUMANITY IRRESPECTIVE OF RELIGION, LOVE ANIMALS, TREES AND ALL OF GODS CREATIONS. IF YOU CAN NOT LOVE AND ADMIRE GODS CREATION, HOW CAN YOU THINK ABOUT ADMIRING THE GREATNESS OF GOD.

Labels:

bio gas,

envo,

envo projects,

etp,

STP

New Delhi, India

New Delhi, Delhi, India

Environmental Entrepreneur,Green Biz.NRN Murthy of Infosys says that we Indians are weak in execution.We need to realize the need and practice of gud project management. Form a group of competent Managers,Give them responsibilities and review the project from day One.

Environmental Entrepreneur,Green Biz.NRN Murthy of Infosys says that we Indians are weak in execution.We need to realize the need and practice of gud project management. Form a group of competent Managers,Give them responsibilities and review the project from day One.

Monday, November 13, 2017

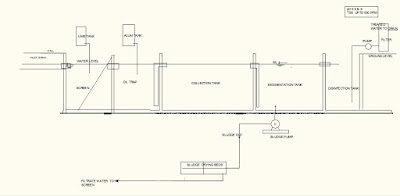

PRIMARY EFFLUENT TREATMENT PLANT (PETP)

PRIMARY

EFFLUENT TREATMENT PLANT (PETP)

PARAMETERS

OF TREATED WATER for HOTELS , HOSPITALS and other industries currently accepted

by Pollution Control Board of Assam. (PCBA)

The

parameters of the treated effluent water will be as under meeting norms of Pollution control

Board (PCBA) .

pH Between 5.5 to 9

TSS (Total suspended solid below 150 mg/liter

BOD( Biological oxygen demand) less than 30 mg/liter

COD(Chemical oxygen demand) less than 250 mg/liter

Oil & grease less than 10 mg/liter

pH Between 5.5 to 9

TSS (Total suspended solid below 150 mg/liter

BOD( Biological oxygen demand) less than 30 mg/liter

COD(Chemical oxygen demand) less than 250 mg/liter

Oil & grease less than 10 mg/liter

IF WASTE WATER FROM HOTEL, HOSPITAL EXCEEDS

THE ABOVE VALUE, ONE PETP IS TO BE INSTALLED FOR TREATING WASTE WATER AND BRING

IT WITHIN LIMITS MENTIONED ABOVE.

Our Consultancy & Supervision scope:

We offer our work on consultancy basis for the Hotels

,hospitals, restaurants, wedding hall, ccar service station, tea garden and

other industries. . All the civil & execution work will be done

by the respective Hotel , under our

guidance from initial survey to the final report submission to the Pollution

Control Board of Assam (PCBA).

1.Preparation

of drawing as per site condition for each

location of hotels , it’s size , their

complexity and need of the hotel

. Thus there is no common solution for all hotels if Customized concept

is adopted , So will provide customized system plant for each

site. Also, at various sites there are exiting septic tanks and other tanks

,pipes etc which can be adjusted in our proposed system which will reduce

construction cost.

2 . We shall Provide a Flow

Chart & project report for

submission to the PCBA

3.We will supervise the progress

of the civil works during construction time of the ETP.

4.We will provide you a

list of dealers from where you can buy

the pump , blower and chemicals.

5..We will train your staff

for first 3 days how to run the plant & provide a maintenance manual for

the plant

6. We will provide a first water test report to be submitted to pollution board

7. We shall help in filling of the Documents to be submitted to the

PCBA . All the legal fees & dues needs to be cleared by the client . The

extra cost for Consent to operate or NOC is not included in the Consultancy

DATA

REQUIRED:

a)Quantity of waste

water generated liter per day

b) Waste Water test report .

.

TREATMENT METHOD OF PETP:

Chemical pre treatment followed by filtration

Flow

Chart of PETP:

IN-Screen—Oil Trap---Collection

Tank---Primary Sedimentation--— ------Disinfection Tank—Pump---Filter ----Out

to drain

Details of different units of the proposed system

A)CHEMICAL

TREATMENT OF WASTE WATER IN PETP

a)

Screen :Waste water will flow through these drains

by gravity flow from the inlet manhole. To remove large floating objects , bar

screens and oil traps are provided inside the incoming drain itself .

b)

Collection tank: All waste water will be collected

here .Lime and Alum will be added here and mixed by air bubbling from a air blower..Waste

water will flow by gravity to the next unit.

c)

Primary Sedimentation tank(PST): The chemical

sludge will be settled here. Waste water will flow by gravity to the next unit.

Sludge is removed by sludge pump to sludge drying beds.

d)Disinfection tank : Disinfection is done here with bleaching powder to

remove colour, bactaria and other

contaminants and than pumped to the pressure

sand filter and finally released to drain.

Labels:

envo,

etp,

PETP,

PRIMARY EFFLUENT TREATMENT PLANT,

STP

New Delhi, India

New Delhi, Delhi, India

Environmental Entrepreneur,Green Biz.NRN Murthy of Infosys says that we Indians are weak in execution.We need to realize the need and practice of gud project management. Form a group of competent Managers,Give them responsibilities and review the project from day One.

Environmental Entrepreneur,Green Biz.NRN Murthy of Infosys says that we Indians are weak in execution.We need to realize the need and practice of gud project management. Form a group of competent Managers,Give them responsibilities and review the project from day One.

Wednesday, May 31, 2017

Waste water Treatment of BGP containing TAR

Tar Removal through Physical Processes Physical processes

will continue to play a very important role for the successful commercial

implementation of gasification. They constitute the basic arm for removing most

of the raw gasifier contaminants, including “tar.” “Tar” is removed mainly

through wet or wet-dry scrubbing. Coalescers, demisters, and cold filtration

are also necessary supplements. These well-known commercial methods are easily

designed and applied, depending on the specific needs of any gasification

process. The main problem arising from “tar” scrubbing is that condensed “tar”

components are merely transferred into another phase (water or solids such as

scrubbing lime), which then has to be disposed of in an environmentally

acceptable manner. The problems associated with the management of these

wastewater or solid residues are summarized as follows: • “Tar” and

“tar”-contaminated solid-waste streams are considered as a special waste;

consequently, their disposal is usually cumbersome and costly. • “Tar”-bearing

wastewater is usually a bi-phasic mixture requiring various steps of treatment

before final disposal. Water insoluble “tar” skimming • Most water-soluble

“tar” components are refractory to the usual biological wastewater treatments.

The applied methods for “tar” and “tar”-containing waste streams include solid

waste stabilization and landfilling, organic phase skimming off the bi-phasic

wastewater-free surface, wastewater incineration, wet oxidation, adsorption on

activated carbon, and final biological treatment. Wastewater contaminants

include dissolved organics, inorganic acids, NH , and metals. 3 Typical values

of COD, BOD, and phenols for wastewater from fixed-bed gasifiers are given in

Hasler et al. (1997). The new BIOSYN design proposes a continuous skimming-off

of insoluble “tar” from the surface of the wastewater. tar-containing

wastewater was treated using lime and alum for the removal of in-organics,

followed by adsorption on powdered activated carbon (PAC) for the removal of

organics. At optimum concentrations, both lime and alum individually proved to

be capable of removing color, total suspended solids (TSS) and total dissolved

solids (TDS), but in both cases, pH adjustment had to be carried out after

treatment. The combination of lime and alum at the dose ratio of 0.8:0.8 g/L

was found to be optimum for the removal of inorganics. The removal efficiency

achieved at optimum concentrations were 78.6, 62.0, 62.5 and 52.8% for color,

alkalinity, TSS and TDS, respectively. Coagulation-precipitation followed by

adsorption on PAC resulted in 92.3% chemical oxygen demand (COD) removal and

100% phenol removal at equilibrium. This technology may prove to be one of the

fastest and most techno-economically feasible methods for the treatment of

tar-containing wastewater generated from BGPs. biomass gasification plant.

The specific technical objectives of this study are: 1.

Identify the optimum individual doses of lime and alum (coagulant) required to

achieve the best treatment efficiency. 2. Identify the optimum and minimum dose

of the coagulant-combination (lime and alum) required to achieve good treatment

efficiency without having to conduct final pH adjustment. 3. Determine the

efficiency of the coagulationflocculation process at optimum coagulant dosage

followed by adsorption on powdered activated carbon (PAC). The iodine value of

PAC was 1050 mg/g. The optimum dose of lime was found to be 0.8 g/L, with

maximum removal efficiency for color, TSS and TDS, and minimum amount of sludge

generation. The optimum dose of alum was observed to be 0.8 g/L with maximum

TSS, TDS and minimum amount of sludge generation. However, the optimum dose of

alum for maximum color removal was found to be 1.0 g/L. Lime was found to

remove ammonia more efficiently than alum. In the lime-alum combination,

lime:alum dose of 0.8:0.8 g/L was found to demonstrate maximum removal of TSS,

TDS, alkalinity, and minimum amount of sludge generation. However, the

lime:alum dose of 0.9:1.0 g/L provided maximum removal of color and ammonia.

The coagulation-flocculation process was found to be more efficient for the

removal of color, TDS, TSS and alkalinity than for the removal of COD and

phenol.

CHARACTERISTICS OF EFFLUENT FROM BIOMASS GASIFICATION PLANT

Parameter Unit Values pH -- 7.49 (±0.015) Color Co-Pt unit 1076.5 (±38.5) TDS

mg/L 1875 (±75) TSS mg/L 82.5 (±2.5) Alkalinity (as CaCO3) mg/L 537.5 (±12.5)

Ammonical Nitrogen mg/L 242.55 (±12.45) Nitrate nitrogen mg/L 0.62 (± 0.02)

Phosphate (as PO4 3-) mg/L 0.12 (±0.03) CODtotal mg/L 3599.5 (±57.5) CODsoluble

mg/L 3499.5 (±57.5) Phenol mg/L 465 (±10) Oil and Grease mg/L 36 (± 4.0) Note:

Values in parenthesis are standard deviation

Labels:

BGP,

etp,

TAR,

Waste water Treatment

New Delhi, India

New Delhi, Delhi, India

Environmental Entrepreneur,Green Biz.NRN Murthy of Infosys says that we Indians are weak in execution.We need to realize the need and practice of gud project management. Form a group of competent Managers,Give them responsibilities and review the project from day One.

Environmental Entrepreneur,Green Biz.NRN Murthy of Infosys says that we Indians are weak in execution.We need to realize the need and practice of gud project management. Form a group of competent Managers,Give them responsibilities and review the project from day One.

Wednesday, May 24, 2017

what is a wastewater treatability study and how does it work?

A wastewater treatability study is a study or a test that

tells us if the wastewater can be treated and how it needs to be treated. If the study is done correctly, it

will clearly identify the problem you’re seeing in your wastewater stream,

helping ensure the proper treatment solutions are considered.

Let’s

just say, for example, that a plant processes metals—maybe a metal plating

facility like a chrome plater or zinc plater—and all of the sudden, they

realize residual metals are present in their wastewater, which are prohibited

to discharge in just about any receiving watershed or municipality.

The company

performing the study would start by taking a sample of their wastewater,

analyzing it (called a characterization study) so they can identify what they

think is the problem through analytical means.

Once

the treatability study is complete and the problem is identified, sometimes a

plant will opt to test different solutions by initially using some conventional

technologies to remove the contaminants from the solution.

Once they

establish that they can removed the contaminants successfully, they will then

scale up the scope of the technology to sufficiently handle the full scale of

the process.

keep in mind that there is usually more than one treatment

available for your problem. A reputable company will perform the treatability

study and recommend different solution for you.

Labels:

etp,

STP,

treatability study,

wastewater

New Delhi, India

New Delhi, Delhi, India

Environmental Entrepreneur,Green Biz.NRN Murthy of Infosys says that we Indians are weak in execution.We need to realize the need and practice of gud project management. Form a group of competent Managers,Give them responsibilities and review the project from day One.

Environmental Entrepreneur,Green Biz.NRN Murthy of Infosys says that we Indians are weak in execution.We need to realize the need and practice of gud project management. Form a group of competent Managers,Give them responsibilities and review the project from day One.

Wednesday, August 31, 2016

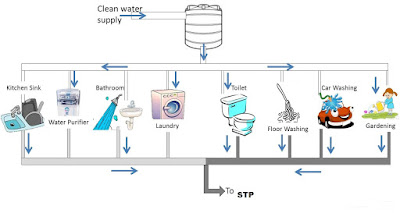

ETP FLOW CHART STP FLOW CHART

Labels:

etp,

flow chart,

STP

Environmental Entrepreneur,Green Biz.NRN Murthy of Infosys says that we Indians are weak in execution.We need to realize the need and practice of gud project management. Form a group of competent Managers,Give them responsibilities and review the project from day One.

Environmental Entrepreneur,Green Biz.NRN Murthy of Infosys says that we Indians are weak in execution.We need to realize the need and practice of gud project management. Form a group of competent Managers,Give them responsibilities and review the project from day One.

Sunday, May 15, 2016

OPERATION MANUAL FOR 10 KLD ETP CHEMICAL DOSE OF ALUM

OPERATION

MANUAL FOR 10 KLD ETP

OPERATION

INSTRUCTION :

1.

The total quantity of waste water from kitchen for which

the ETP is designed is 10,000 liter per day. The unit functions 8 hours in a

day .There is no flow at day.The ETP is designed for continuous flow treatment

of effluent at a average flow rate of 1250 liter per hour. The air blower will

have to be run continuously for mixing of chemicals in reaction tank and

flocculation tanks.

2.

Allow all the effluent of the day generated to enter the

underground collection tank. Collected effluent is planned to be pumped

continuously for eight hours at a average flow rate of 1250 liter per hour .

The plant and machinery cant take more than this flow.

.

CHEMICAL DOSING :

1.

Lime,

add 20 Kg per day to maintain pH at 10 at collection

tank. Check pH at Collection tank after adding lime manually. pH

maintaining is extremely important or alum will not work properly. Use it up in

one day.

2.

Alum, add 15 Kg in the auto doser tank of the reaction tank in 100 liter of water and

use it up in one day. pH will come down to 8 after addition of alum.

3.

PAC,

add 100 gm in the auto doser tank in the flocculation

tank and use it up in one day.

COMMON INSTRUCTION FOR ETP :

1. When

the pumps are on, the blower must be on also for mixing the chemicals with

water. Note down the time in log sheet.

2.

The Auto doser for alum in reaction tank should be on

when pump is on. Note down the time in log sheet

3.

The Auto doser for PAC in flocculator should be always

on continuously when pump is on. Note down the time in log sheet

4.

Fill the auto doser tank with fresh water and mix the

estimated chemical in it for the day and set it at the desired dose. Note down

the time and quantity in log sheet

5.

Preventive maintenance of pumps and blowers like oiling

etc should be regularly done.

6.

Note down the pH of the inlet and outlet water and note

it at log sheet.

7.

The waste sludge from tube settler is to be suitably

disposed off to the sludge drying bed by opening the valve provided at the

hopper bottom of the tube settler.

8.

Backwash the Sand filter and carbon filters after each 4

hours.

9. Raw

and treated effluent is to be analyzed periodically for pH, TSS, BOD and O&G.

.

10.Skilled Operator will be required to carry out all these instructions.

11.The

operator will maintain a log book. And chemical stock registers.

12.

The performance of the ETP is dependent on the proper skill of the operator and

proper chemical dosing.

Labels:

alum dose,

chemical dosing,

etp,

ETP manual,

manual

New Delhi, India

New Delhi, Delhi 110001, India

Environmental Entrepreneur,Green Biz.NRN Murthy of Infosys says that we Indians are weak in execution.We need to realize the need and practice of gud project management. Form a group of competent Managers,Give them responsibilities and review the project from day One.

Environmental Entrepreneur,Green Biz.NRN Murthy of Infosys says that we Indians are weak in execution.We need to realize the need and practice of gud project management. Form a group of competent Managers,Give them responsibilities and review the project from day One.

Saturday, May 14, 2016

Polishing pond for Magur fish in ETP treated water.

Oxygen level in the tanks should exceed 3

mg/l. If the magur fish tanks are supplied with turbid water it is advisable to

filter it with through a sand filter and to aerate the tanks at night for maintaining

oxygen level by using an air blower The aeration grid should be one feet above

the bottom of the tank so that mud can settle at the bottom..Magur requires

mud. .

A tank containing such a fish group required

approximately 5 liter/min water supply. Depth of fish tanks should be 0.5–0.75

m. Let us take water depth 0.75 meter.The freeboard of the tank should be 0.5

meter so that fish don’t jump out. So total depth of tank is 1.25 Meter. Volume

of the tank should be 10,000 liter. Normally it should be square in size. So

length and width of tank will be 4 Meter by 4 meter.

For avoiding the direct contact between tank wall

and fish it is better to cover the inner surface of tank with polyethylene

sheet.

Inlet water should be

sprayed in the tank from a perforated PVC tube throughout the length.

Outlet water will overflow

from a overflow weir at the outlet side. The top of the overflow weir will be

covered by net/mesh. The proper mesh size is 1.0–1.5 mm

Most efficient way of

plankton maintenance is frequent manuring with small doses of poultry or cattle

manure. In addition to plankton maintenance, frequent manuring maintains an

active and effective bacterial population in pond water. It facilitates

decomposition of metabolites hampering fish growth. Poultry (5–15 kg/bigha) or

cattle (10–20 kg/bigha) manure is sufficient for frequent treatment of pond.

Daily brushing of wall and

bottom of the tanks is essential. Moreover, when there is deterioration in

water quality, 10–20 % fresh water replacement is suggested.

Lime is used for killing

different living organisms remaining in muddy pools after dewatering of ponds.

IF MAGUR SURVIVES IN THE POLISHING TANK, IT MEANS

THE ETP IS RUNNING PROPERLY.

TANK SIZE : 4 x 4 x 1.25

Meter. Water depth = 0.75 Meter. Free Board=0.5 M

Labels:

etp,

fish,

magur fish,

Polishing pond,

Treated water

New Delhi, India

New Delhi, Delhi 110001, India

Environmental Entrepreneur,Green Biz.NRN Murthy of Infosys says that we Indians are weak in execution.We need to realize the need and practice of gud project management. Form a group of competent Managers,Give them responsibilities and review the project from day One.

Environmental Entrepreneur,Green Biz.NRN Murthy of Infosys says that we Indians are weak in execution.We need to realize the need and practice of gud project management. Form a group of competent Managers,Give them responsibilities and review the project from day One.

Friday, April 22, 2016

WASTE WATER TECHNOLOGIES

Labels:

etp,

STP,

WASTE WATER TECHNOLOGIES

New Delhi, India

New Delhi, Delhi 110001, India

Environmental Entrepreneur,Green Biz.NRN Murthy of Infosys says that we Indians are weak in execution.We need to realize the need and practice of gud project management. Form a group of competent Managers,Give them responsibilities and review the project from day One.

Environmental Entrepreneur,Green Biz.NRN Murthy of Infosys says that we Indians are weak in execution.We need to realize the need and practice of gud project management. Form a group of competent Managers,Give them responsibilities and review the project from day One.

Sunday, March 13, 2016

SOLID SEPARATOR DRUM SCREEN FOR ETP FROM ENVO

SOLID SEPARATOR / DRUM SCREEN

IT IS USED FOR SEPARATING SOLID PARTICLES FROM LIQUID WASTE.

SPECIFICATION OF DRUM SCREEN

IT IS USED FOR SEPARATING SOLID PARTICLES FROM LIQUID WASTE.

VIDEOS OF SOLID SEPARATOR DRUM SCREEN

SPECIFICATION OF DRUM SCREEN

SS 304 mesh with hole , Basket Size

Diameter 1000

mm,

Length 2000 mm with inside conveyor &

support roller, Elecon

Make gear box & Crompton make 3

HP Motor and double

chain sprocket

WE SUPPLY THIS ITEM ON ORDER.DELIVERY TIME 30 DAYS

Labels:

drum screen,

envo,

etp,

separator,

solid separator,

STP

New Delhi, India

New Delhi, Delhi 110001, India

Environmental Entrepreneur,Green Biz.NRN Murthy of Infosys says that we Indians are weak in execution.We need to realize the need and practice of gud project management. Form a group of competent Managers,Give them responsibilities and review the project from day One.

Environmental Entrepreneur,Green Biz.NRN Murthy of Infosys says that we Indians are weak in execution.We need to realize the need and practice of gud project management. Form a group of competent Managers,Give them responsibilities and review the project from day One.

Friday, March 11, 2016

ETP FROM SCRAPE MATERIAL --- BIO TOWER

BIO TOWER at Standard Agro,Unnao in 2012 from scrape material..

We created an ETP from scrap tanks available at the site. The shape of the available tanks made us design it as Bio Tower. Alll the owner has to buy is 1)A new Air Blower,2)A New Pump and 3) Some new Pipes.

Now it is running successfully.

We created an ETP from scrap tanks available at the site. The shape of the available tanks made us design it as Bio Tower. Alll the owner has to buy is 1)A new Air Blower,2)A New Pump and 3) Some new Pipes.

Now it is running successfully.

New Delhi, India

New Delhi, Delhi 110001, India

Environmental Entrepreneur,Green Biz.NRN Murthy of Infosys says that we Indians are weak in execution.We need to realize the need and practice of gud project management. Form a group of competent Managers,Give them responsibilities and review the project from day One.

Environmental Entrepreneur,Green Biz.NRN Murthy of Infosys says that we Indians are weak in execution.We need to realize the need and practice of gud project management. Form a group of competent Managers,Give them responsibilities and review the project from day One.

Tuesday, July 07, 2015

PROF DR.ABUL FAIZ SYED ABDUL AOWAL, DELHI COLLEGE OF ENGG,NEW DELHI

MY FIRST JOB IN HIS COMPANY NATIONAL ASSOCIATE

LEARNED ABCD OF DESIGN FROM HIM IN HIS OWN HAND WRITTING

PROF DR.ABUL FAIZ SYED

ABDUL AOWAL, DELHI COLLEGE OF ENGG,NEW DELHI, (BIRTH, 1938

JORHAT,ASSAM---- DEATH,2004,GUWAHATI,ASSAM), SON OF DR. SYED JAMALUR RAHMAN AND

SYEDA ANWARA BEGUM.

1.

POSTINGS :

(a)

Junior Engineer , Assam State Electricity Board, (1961- 62)

(b)

Lecturer , Civil Engg. Assam

Engg. Collage , Guwahati , Govt. of Assam , (1962-69)

(c)

Asstt. Professor, Civil Engg. Assam Engg. Collage, (1969-71)

(d)

Executive Engineer , Town & Country Planning Deptt. Govt

. of Assam , (1971-73)

(e)

Executive Engineer , Public Health Engg. Deptt.., Govt. of

Assam , (1973-75).

(f)

Professor in Environmental Engg. Delhi College Of Engg, Delhi

Administration, Delhi- 110006,since 1975 –Retired.

2.

CONSULTANCY

SERVICES :

Had done consultancy works in the

field of pollution control as a consultant of the:

(a)

National productivity council

(b)

Delhi productivity council

(c)

Central Board for the prevention and control of pollution

(C.P.C.B.)

(d)

Tamil Nadu pollution control Board

(e)

U.P. pollution control Board

(f)

Assam pollution control Board

(g)

Haryana pollution Control Board

(h)

Punjab Pollution Control Board

(i)

Delhi Collage of Engg. Helping as Adviser

(j)

Indian Institute of Ecology & Environment etc.

3.

INVENTIONS:

The following inventions are made:-

(a)

AOWAL FILTER : Design and construction of an iron eliminator

for hand pumps . This design has been adopted by the P.H.E. Dett., Govt. of

Assam for which he never got any official recognition from his department, but everyone knows about it..

(b)

Design and Fabrication of portable Effluent Treatment Plant

for waste water from Oil Drilling . This has been successfully demonstrated in

the field at Duliajan , Assam to Oil India and O.N.G.C. officials.

(c)

Design and febrication of an Electro- flocculation Device

for colloidal waste water treatment like pulp and paper mill waste textile mill waste , tannery waste ,

distillery waste . This has been patronised by Tamil Nadu pollution control

Board and demonstrated at Erode and coimbatore, T.N.

(d)

Design and Febrication of a Dye recovery system from textile

mill effluent – project patronised by D.S.I.D.D.C

(e)

S.R.P (Sludge Reagent product ) method of treatment of

Drinking water . This reduces cost of conventional treatment of water by half ,

this method is already patented.

(f)

S.R.P. method of chemical Treatment of Sewage . This mothod

is cheaper in capital cost equal in running cost as compared to the biological

treatment and is free from odour and insect nuissance .This is also patented.

(g)

A new type of upflow septic tank is designed and installed

in a number of places . The biggest one is installed in the market place of

Durgapur . About 12 are working for the last 10 years in Okhla, New Delhi . It

requires a Soak pit , it has a far better effluent water quality and cost is

40% less than the conventional septic tank

(h)

A cheap method of desalination of sea water by using ultra

sound and electro flocculation . very encouraging results are seen in the lab .

prototype experimentation with actual sea water is expecteed in collaboration

with the Govt. of Tamilnadu.

4. OTHER ACTIVITIES:

(a)

Head of Deptt. of CivilEngg. ., Delhi collage of Engg., Delhi.

(b)

Guiding post Graduate and undergraduate project work . About

50 M.E. projects 2 ph. D. projects are completed .

(c)

Expert of the U.P.S.C.

(d)

Member Faculty of Technology , University of Delhi.

(e)

Member University Court , University of Delhi.

(f)

Ex Member , Academic Council , University of Delhi.

(g)

Chairman , I.S.I. Committee CDC-26

(h)

Ex-Dean, Faculty of technology , University of Delhi

(i)

Member , Engineering courses committee , Jamia Millia Islamia,New Delhi

5.

MEMBERSHIP OF PROFESSIONAL BODIES:

(a)

Life Member , I.W.W.A.

(b)

Member , I.A.P.C.F.

(c)

Member , I.W.P.C.F.

(d)

Member , I.P.H.E.

(e)

Member , Bio. Soc. Ind.

HE WAS ADVISER TO MANY ENTREPRENEURS LIKE ME.

MONDAY, NOVEMBER 29, 2004

Dr.A.F.S.A. Aowal is no more

A VERY SAD NEWS :

Dr.A.F.S.A. Aowal is no more.He passed away this evening at 05-30 at

guwahati,assam.----- Original Message -----

From:

To: saleem

Sent: Tuesday, November 30, 2004 10:09 AM

Subject: Re: Dr.A.F.S.A. Aowal is no more.

> Asalaamu Alaikum,

> Ina Lillahi Wa Ina Ilaihi Rajioon !

> We are shocked and distressed to hear of this news.

> My father Haji M Miakhan is quite upset at hearing of this news.

> We have very fond memories of Dr Aowal that cannot be forgotten, ever.

> We pray that the Almighty give him peace and tranquility forever.

> Since my father is not keeping well, kindly convery our heartfelt

condolencences

> to his family.

> Haji M Miakhan

> Khan Md Ashraf

A VERY SAD NEWS :

Dr.A.F.S.A. Aowal is no more.He passed away this evening at 05-30 at

guwahati,assam.

Dr.A.F.S.A. Aowal is no more.He passed away this evening at 05-30 at

guwahati,assam.

----- Original Message -----

From:

To: saleem

Sent: Tuesday, November 30, 2004 10:09 AM

Subject: Re: Dr.A.F.S.A. Aowal is no more.

> Asalaamu Alaikum,

> Ina Lillahi Wa Ina Ilaihi Rajioon !

> We are shocked and distressed to hear of this news.

> My father Haji M Miakhan is quite upset at hearing of this news.

> We have very fond memories of Dr Aowal that cannot be forgotten, ever.

> We pray that the Almighty give him peace and tranquility forever.

> Since my father is not keeping well, kindly convery our heartfelt

condolencences

> to his family.

> Haji M Miakhan

> Khan Md Ashraf

From:

To: saleem

Sent: Tuesday, November 30, 2004 10:09 AM

Subject: Re: Dr.A.F.S.A. Aowal is no more.

> Asalaamu Alaikum,

> Ina Lillahi Wa Ina Ilaihi Rajioon !

> We are shocked and distressed to hear of this news.

> My father Haji M Miakhan is quite upset at hearing of this news.

> We have very fond memories of Dr Aowal that cannot be forgotten, ever.

> We pray that the Almighty give him peace and tranquility forever.

> Since my father is not keeping well, kindly convery our heartfelt

condolencences

> to his family.

> Haji M Miakhan

> Khan Md Ashraf

Labels:

aowal,

aowal filter,

DCE,

delhi college of engineering,

Delhi university,

dr aowal,

DU,

environmental engineering,

etp,

STP

New Delhi, India

New Delhi, Delhi, India

Environmental Entrepreneur,Green Biz.NRN Murthy of Infosys says that we Indians are weak in execution.We need to realize the need and practice of gud project management. Form a group of competent Managers,Give them responsibilities and review the project from day One.

Environmental Entrepreneur,Green Biz.NRN Murthy of Infosys says that we Indians are weak in execution.We need to realize the need and practice of gud project management. Form a group of competent Managers,Give them responsibilities and review the project from day One.

Subscribe to:

Posts (Atom)